must.Cooling system ensures actual engine operation without any hazard or danger.Proper cooling system

increase engine efficiency.

Cooling system performs the following three functions:

1.it prevents overheating of the engine by removing excess heat

2.it keeps the engine at normal operating temperature

3.it provides a source of heat for the passenger compartment heater and air conditioner

Engine cooling system has five basic parts -

water jackets, water pump, thermostat, radiator, and fan

Water pump:

Water pumps are centrifugal (impeller) pumps.The pump is driven by either a belt (fan belt) from the crankshaft pulley or by gear.The pump discharge is in the order of 28,000 litres/hr.The impeller shaft is supported on sealed bearings which never need lubrication.

Engine fan:

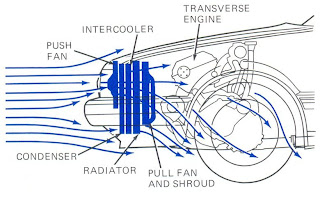

Engine fan or cooling fan provides additional air through the radiator.The fans are either mechanical or electrical fans.The fan is made of steel sheet or moulded plastic.It has four to seven blades.A fan shroud is used to direct the air flow.Variable speed fan is sometimes used with longitudinal engines.A thermostatic fan clutch and silicone oil fluid coupling controls the speed of the engine.Flexible blade fan reduces the power needed and reduces fan noise.the pitch of the blade decreases as fan speed increases.

Electric fan is driven by an electric motor through a thermostatic switch generally transverse engines use electric fans.electric fan drains less power from the engine and usually quieter than the mechanical fans.

Radiator:

Radiator is a heat exchanger that removes heat from the engine coolant a radiator has three main partsradiator core, and inlet and outlet tanks.the radiator core is made of aluminium and has two sets of passages, a set of tubes, and a set of fins attached to the tubes inlet and outlet tanks are made of plastic or metal.

Radiators may be classified according to the direction of fluid flow-

down (vertical) flow radiator: Oldest type of radiator and is designed to use the downward flow caused by natural convection

cross flow radiator:Used to make way for lower bonnet lines.Normally hot inlet is situated higher than the outlet

Sometimes transmission oil cooler is fitted with outlet tank for cars with automatic trans axle or transmission.

Some radiators have expansion tank connected by an overflow or transfer tube to the radiator filler neck.

Eliminates coolant loss by surging of the coolant during heavy braking.Prevents water from boiling during long hill climbs.Raises the working temperature thus improves engine efficiency.Allows a smaller radiator to dissipate as much heat as a larger one operating at a lower temperature.

Expansion tank:

expansion tank eliminates air bubbles from the coolant which makes it more efficient. Sometimes four heat exchangers are cascaded together - nearest to the engine is the cooling system radiator. Other heat exchangers are engine oil cooler, air-to-air inter cooler, and air-conditioner condenser. There are two fans in this type of cascaded system.

Thermostatic valve:

Thermostat is a heat-operated valve that regulates coolant temperature.thermostat is placed in the coolant passage between the cylinder head and the radiator.in reverse-flow cooling system, the thermostat is placed between the lower radiator hose and the engine.thermostat opens at a specific temperature, known as the thermostat rating - two common ratings are 85C and 91C

Another great reason to use a crock pot for your summertime cooking is the simplicity of washing up. Unlike traditional cooking with several pots and pans, most crock pot meals are made in one pot.Refrigeration Equipment

উত্তরমুছুন