CATALYTIC CONVERTERS (CC): Catalytic converters are the most effective device to control automobile exhaust emission.This is mainly for SI engine emission control.There are two types of catalytic converter 3-way and 2-way catalytic converter.Among them 3-way catalytic converter is most effective for controlling automobile emission.Typically used for SI engine emission control.

2-WAY Catalytic Converter : Removes CO and HC

3-WAY Catalytic Converter : Removes NOx, CO and HC

Catalytic Converter Efficiency = {1 – (mexhaust out / mexhaust in)} x 100 %

A CC may have different removal efficiencies for different components.

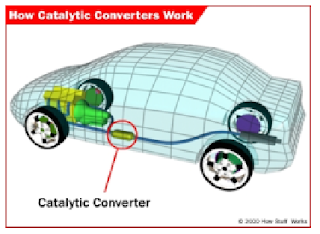

This figure is showing the place where CC is most effective and it can work without influence of engine temperature.For proper working of CC it need a optimum engine temperature, this is why it is necessary to

find out the place where the engine temperature is optimum.

The Alumina wash coat ( about 20 µm) containing the noble materials is used to enhance the surface area (100-200 m2/g) of chemical reaction.

HOW CATALYTIC CONVERTER WORK: The working procedure of a catalytic converter is basically based on different catalyst and different chemical reaction which change harmful gases into clean gases.

Catalysts (Noble metals) :

Platinum(Pt), Rhodium (Rd), Palladium(Pd); About 4-5 g/cat converter.

CC could be either Monolith(Honey-comb) or Pellet(Bead) type.

2-Way Catalytic Converter : Catalysts - Pt, Pd

Oxidation reaction : CO + O2 → CO2 HC + O2 → CO2 +H2O

3-Way Catalytic Converter : Catalysts - Pt, Rd, (Pd)

Reducing reaction :

NO + CO → ½ N2 + CO2 2 NO + 5H2 → 2NH3 + 2H2O

NO + H2 → ½ N2 + H2O 2NO + 5CO + 3H2O → 2NH3 + 5CO2

Oxidation reaction : CO + O2 → CO2 HC + O2 → CO2 +H2O

• 3-way catalytic converters work best with engines having precise control of air-fuel ratio. Many of them use O2 sensors incorporated at the exhaust, communicating with the engine management system.

Specially the NOx reduction reaction requires very accurate air-fuel ratio, regular carburetors and simple fuel-injection are simply too inaccurate to keep up to the requirement.

• Catalytic converters stars working effectively as they get warm above 250-300°C. The reactions taking place are exothermic. Converter material should be able to with stand up to 1000°C. Generally heat

shields are used to protect other parts of the vehicle body.

• Extra oxygen is needed to support the reactions, that might be provided by lean air-fuel ratio or pump-type air injection.

A Catalytic Converter specification:

Engine displacement : 1.5 liter,2000cc

Engine speed : 2000-3000 rpm

Minimum operating temperature : 250 C

Maximum allowable pressure : 800 C

Maximum allowable back pressure : 2 psi

Fuel specification : Unleaded, S-content

Maximum pollutant in intake : HC,CO,NOX

Pollutant reduction efficiency : 70% of HC, CO

Expected life : 100,000 km

Catalytic Converter Performance:

• Unleaded (Pb free) fuel is essential to prevent ‘Fouling’ of Catalytic converters.

• Most common cause of failure is an engine that pumps too much unburned fuel, which can overheat or

carbon-clog the catalyst.

• Fuel specification like Sulphur content should be maintained to prevent catalyst poisoning decorating

performance.

• Fouling, clogging, meltdown, breakage of ceramic substance may cause a converter to stop doing its job,

and/or plug it and raise back pressure.

• In most automobiles you need to use a silencer in addition the

catalytic converter to achieve desired low noise level.

কোন মন্তব্য নেই:

একটি মন্তব্য পোস্ট করুন